The functional reliability of a machine or industrial plant can only be achieved by protecting its hydraulic and lubrication circuits using quality filter elements. Saving on these components is never a good idea and with Fai Filtri quality hydraulic filters avoid costly damage

Four and a half euros in immediate savings and 15 thousand euros in damages a few months later. The idea of containing the maintenance costs of a hydraulic system that at the time cost 700 thousand euros by inserting Asian filter elements cost an Italian entrepreneur dearly. The new filters, although apparently similar to those to be replaced, actually had nothing similar in terms of accumulation power and after a few weeks they stopped performing their function.

With the result that the circulating oil gradually became dirty and the solenoid valves did not like it. “Unfortunately, says Roberto Pasotto, owner of Fai Filtri, the risks that are run by equipping a machine or a system with low-quality filter elements are not immediately perceptible, while the economic savings are concrete. If an entrepreneur looks to the immediate and not to the future, unpleasant surprises are the order of the day”.

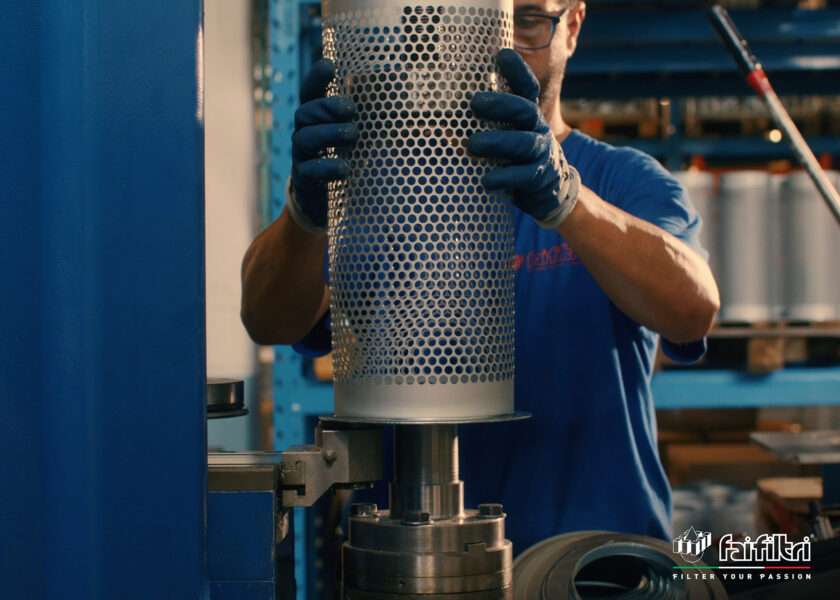

But how can you distinguish a quality filter from a mediocre one? “Given that initially the performance between the two products can also be similar and therefore the comparison should be made in statistical terms and keeping an eye on the progressive deterioration of the fluid operating in the machine or system, the quality of a filter can be evaluated starting from a visual analysis of the more technical structural and functional characteristics. A quality filter must be clean and well finished with the external sheet metal body free from signs of processing induced by poorly cared for production processes or the use of inadequately treated materials.

Then opening the filter must be in the presence of a homogeneous filter septum, characterized by folds of uniform height and regularly distributed over the entire diameter, without compressed or excessively open areas. The geometry of the folds is also a critical element. It must be well defined and constant along the entire surface. Furthermore, all the layers that make up the filter septum must be perfectly cohesive with each other, without detachments or misalignments. Another distinctive sign is the quality of the joints and gluing.

There must be no visible glue smudges and the joints must have a linear and uniform bead. In short, it happens that a quality filter is recognized by the attention to detail, the construction precision and the choice of materials, while the weight of the filter media is not synonymous with quality. A very dense media may seem more efficient, but in reality it is just poorly designed, without taking into account that the quality of a filter depends on the balance between materials, filtering efficiency and mechanical resistance, not simply on the overall weight of the cartridge”.

Which by the way are not all the same. “Absolutely. The filtration market is characterized by diversified needs that vary based on the application sector, operating conditions and regulatory standards. For this reason, Fai Filtri does not only offer standard products, but develops customized solutions based on the specific requests of customers, with a production flexibility that allows to respond quickly and efficiently even to particular requests, always ensuring maximum quality and reliability. In fact, it happens that even if two filters may visually appear similar, they have nothing in common”.

What changes? “First of all, the aforementioned filter media, the heart of the filter, made with different materials and available with relative, nominal or absolute filtration values aligned with the needs of use. The media determine the efficiency of separation of impurities. No less important, however, are the adhesives needed to ensure cohesion between the various components of the filter cartridge. They must be resistant to high temperatures and compatible with a wide range of fluids to be filtered, exactly as happens for the reinforcing sheets that constitute the load-bearing structure of the filter.

Alternative materials such as glass-filled nylon are also possible for special applications, in particular those where the differential pressures are not high, but the geometries of the components are complex. Glass-filled nylon offers an excellent combination of mechanical resistance and lightness, facilitating the production of structurally complex components where the use of sheet metal would be less practical. It is important to point out, however, that the filter septum is the main component of the filter and its composition plays a decisive role in the efficiency of the filtration system.

The choice of filter material must be carefully evaluated based on the specific application and the level of protection required for the system components. Since the filter media is the key factor that influences the degree of cleanliness of the fluid, it is essential to select it with precise criteria, taking into account the operational needs and the sensitivity of the parts to be protected. It is no coincidence that Fai Filtri constantly invests in research and development to always introduce new filtration technologies aimed at improving the performance of its products and introducing new ones.

Great attention is also paid to the environmental sustainability of the products themselves and their respective production processes in terms of reducing energy consumption, waste and resources”. However, all this comes at a cost. “Certainly, continues Roberto Pasotto, we cannot compete with Asian manufacturers, too often supported by their respective states, but the price difference between a cheap filter and a quality one is not high, while the advantages brought by the latter are.

An effective filtration system actually helps protect the sensitive components of the machines, guarantees consistent performance over time and minimizes the risk of breakdowns or malfunctions. This is because it retains impurities and contaminants present in the fluid, preventing harmful particles from reaching the critical components of the system, causing pressure variations, blockages and unexpected malfunctions. An effective filter also plays a crucial role in preventing abnormal wear and allows for extended scheduled maintenance intervals, thus reducing the frequency of replacements and cleaning operations. This translates into significant economic savings not only on spare parts, but also on costs related to machine downtime. Without forgetting that less contamination of the fluid allows for its characteristics to be preserved over time, reducing the need for frequent changes”.

Si fa ma non si dice

Fai Filtri is a company specialized in the design and production of filters for industrial and hydraulic applications, operating in the sector for more than 45 years. The headquarters are in Italy, but the presence is global, guaranteed by branches, distributors and partners located in numerous countries. The result is a network that allows for a turnover of approximately 24 million euros per year, part of which is constantly reinvested in new production technologies and in research and development.

This main productions include filter elements for hydraulics, air-oil separation for compressors and electrical discharge machining and each sector is approached with aftermarket components whose quality standards are completely comparable to those of the original manufacturers which, in some cases, are produced by Fai Filtri, exactly like some filter elements used in motorcycle racing by top-level teams which, however, for contractual reasons, cannot be mentioned. In practice, an industrial group that is not just a filter manufacturer, but rather a strategic partner for companies looking for reliable, innovative and tailor-made solutions for their needs.

Titolo: Fai Filtri: perchè scegliere filtri idraulici di qualità evita danni costosi

Autore: Redazione